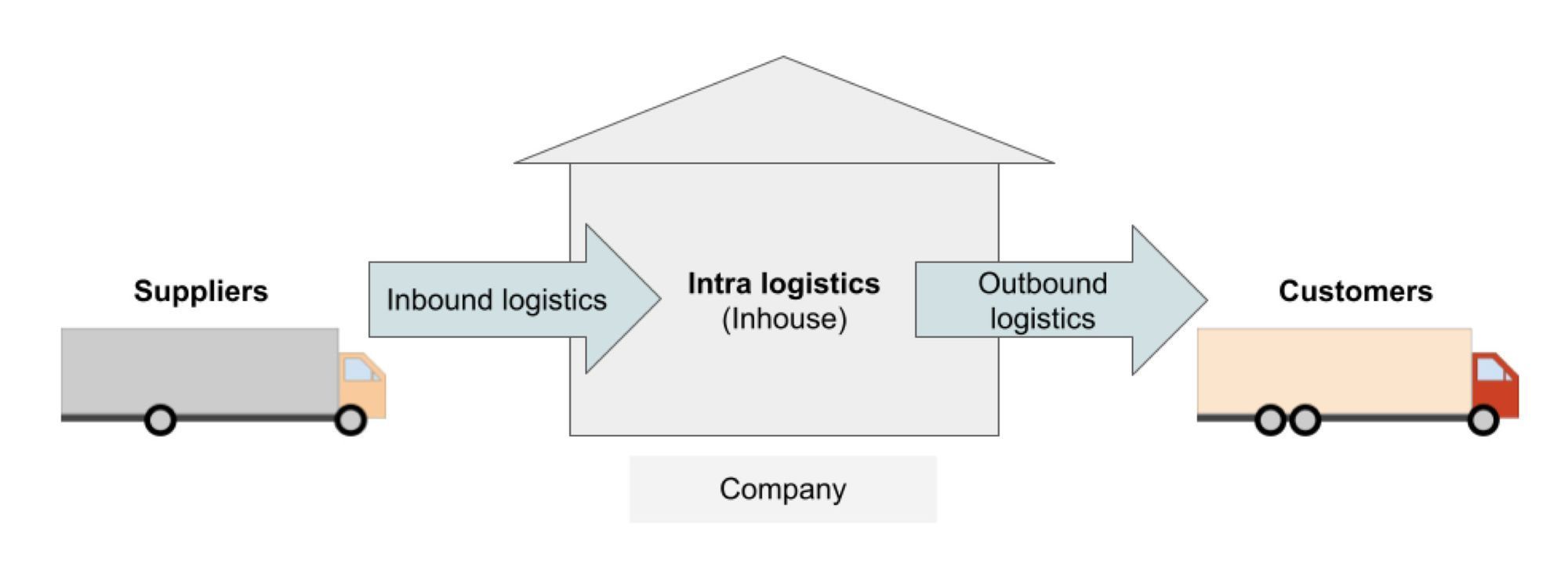

Enterprise logistics providers offer a multi-layered solution that includes warehousing, transportation, storage, and end-delivery of goods with maximum efficiency. These sub-operations require management for two kinds of supply-chain operations, Inbound Logistics and Outbound Logistics.

How Outbound Logistics is shaping modern businesses

When it comes to running a successful logistics operation, time is of the essence. Whether the end-customer is a wholesaler, retailer, or the end consumer, everyone wants their product to reach them in the fastest and most efficient way possible.

At the same time, the introduction of e-commerce has pushed demand through the roof leading to companies needing to ramp up their supply chain to catch up with it.

“ With great demand comes great revenues, and an even greater cost of doing business ”

The increasing demand has led to most companies increasing their expenditure for logistics, which means

- building more warehouses & storage facilities

- acquiring more trucks

- increasing the number of distribution channels

and so on, all contributing to increasing cost of business. In India, logistics account for 13-14% of the product cost which is more than twice a global average of 6%. This high cost of logistics is mainly attributed to wastage caused by inefficient logistics which has been plaguing Indian businesses for a very long time. This cost is eventually passed on to the consumer, increasing the retail price of goods and pushing consumers to find cheaper alternatives.

"The domino effect of inefficient outbound logistics has been affecting the revenues of businesses both directly and indirectly".

Problems with traditional Outbound Logistics system

Most businesses around India are still stuck with a decade-old system of outbound logistics. As a result, it did not take advantage of the technological revolution in logistics & supply chain management. Businesses that were early adopters of technology in their logistics management enjoyed a competitive edge over other companies as they,

- reduced the cost of doing business

- set-up an efficient supply-chain system

- received higher market & revenue growth.

Let’s have a look at some of the most fundamental problems with the traditional system of logistics management

1. Lack of transparency remains one of the key issues in transportation

Due to the large number of stakeholders involved in any logistics operation, transparency has always been a key issue. Tracking hundreds of vehicles and their whereabouts through traditional methods like phone calls is not sustainable anymore. The delivery and health of goods can only be checked at delivery stations, making the entire process opaque and prone to mismanagement, theft, and unfair practices on the route.

2. Lack of GPS tracking and time management leads to delayed deliveries and unfulfilled commitments

The Indian logistics operation is notorious for failing to deliver goods on time due to end number of factors like,

- Unwanted stops by the driver

- on-route vehicle breakdown

- lack of route planning among other issues

- lack of tracking

This severely affects the timely delivery of goods as fleet managers rely on the vehicle’s driver for location data that are not always accurate. In the case of time-sensitive goods like medical supplies, vaccines, or cold-storage goods, late delivery can often turn into rejected shipments due to which companies incur a heavy loss.

3. Poor Inventory Management and lack of data-driven decisions

Manual inventory keeping is a time-consuming task and often prone to human errors. Large business operations have a very dynamic supply and demand to their scale of operation. Processes like

- warehouse management

- stocking of goods and placing orders

- order management

among others have become extremely inefficient. Over-reliance on manual management leads to lapses in inventory management causing issues like

- overstocking or understocking of goods

- inaccurate supply and demand estimation

- unfair practices

- warehouse inefficiency

All of this makes the inventory management process extremely complicated, irregular, and inefficient.

There are several other problems related to the traditional management of outbound logistics, which range from a poor workforce and delivery productivity to inefficient in-plant operation, resulting in considerable delays, especially for weighing goods. These inefficiencies raise the operational cost and severely impacts their competitiveness when compared to technology-driven businesses while cutting into growth revenues and profits.

Role of technology in optimizing Outbound Logistics

There are plenty of logistics and supply-chain operations that provide complete optimization using the data and technology to streamline and modernize the outbound logistics system.

1. GPS or SIM-based Vehicle Tracking System can help track the progress of the on-route fleet

Businesses can equip their entire fleet with a vehicle tracking system that will allow fleet managers to keep track of all the on-route vehicles from a single dashboard. Tracking systems can give real-time location 24x7 increasing efficiency, productivity, and quick support in accidents or emergencies. It will also prevent unwanted stops and increase transparency in the entire outbound logistics process.

2. Scheduling and Routing system can initiate more efficient utilization of vehicles reducing operational cost

Using Scheduling and Route systems businesses can pre-plan the entire trip by choosing the most efficient route for delivery of goods based on previous trip data. It would certainly help in more time-bound delivery of goods, something the logistics industry dearly needs. Apart from that scheduling can help divert a single vehicle to make multiple pick-ups and drops along the way to maximize efficiency minimizing idle trips.

3. In-plant logistics solution can streamline inventory management and improve the plant transport network

In-plant logistics solutions provide a complete plant logistics automation solution related to the movement of vehicles, loading & unloading of goods, and weighbridge operations. Using technology like RFID tracking, automated weighing, etc, businesses can Regularize, Automate, and Track the movement of goods and vehicles inside their facility avoiding chaos. It also can prevent unfair practices and irregularities in the weighing process by automating the weighbridge system.

4. Optimizing cost for outbound logistics with a data-driven approach can same company crores annually

A data-driven logistics management system collects and makes sense of various data like trip details, inventory size, etc to provide the most effective inventory and transport solution. Every process in the supply chain can provide meaningful insights to improve each process,

- trip data for better route planning & fuel management

- traffic data for time optimization

- sales data for better inventory management

- driver data for increasing productivity

- other data

Relying on this data and optimizing the process has saved a lot of money for these businesses.

5. Communication specially for B2C businesses is crucial in gaining consumer trust and retaining them

Communication of the status of an ordered product has pretty much become standard in the market today. Effective communication drives consumer sentiment hence it is important to make communication accessible and clear. It has been made possible due to a tech-backed, integrated logistics and supply-chain system that increases transparency, as seen in new-gen 3PL providers.

What should your business do?

The adaptation of technology into logistics is crucial for efficient operation and to stay competitive in the long term. Businesses with pre-existing logistics can equip their operations with technology through logistics solutions offered by Fleetx. It allows them to modernize their operations with solutions like fleet management, driver management, etc that reduce inefficiencies from the on-route vehicles and drivers. It also reduces the risk of accidents by monitoring driver’s performance like keeping speed-in-check, fatigue, total driving time among others.

Additionally, traditional businesses can transition to a more technology-driven operation by opting for fleetx’s enterprise solutions like transport management system and in-plant logistics which offers a swift transition to insight & technology-driven system from a traditional one without disruption and at a much lower cost.